Note that ANSI/ASQ Z1.4-2008 defines AQL as the “Acceptance Quality Limit.” It explicitly states, “the use of the abbreviation AQL to mean Acceptable Quality Level is no longer recommended” (ASQ, 2008, p. These AQLs are approximate because they are derived from the ANSI standard that assumes a fixed sample size, unlike the DOT&E protocol in which the sample size can vary if a perforation is observed.

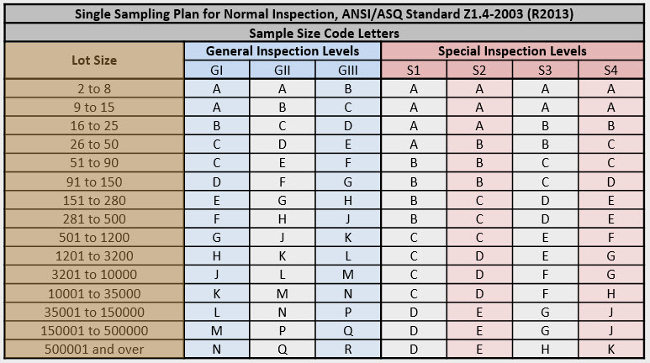

The DOT&E LAT protocol states that the “UTL (at 90 percent confidence) will be calculated by combining the right and left shot locations if the data from the qualifying First Article Test indicates the data from the side locations can be combined for analysis.” This procedure is different from the DOT&E FAT protocol in which back and front DOT&E, 2012, pp. However, unlike FAT where the UTL was also fixed at 90 percent, the UTLs for LAT vary with lot size (and hence with sample size): 80 percent UTL for lot sizes of 501 to 3,200 helmets, 75 percent UTL for lot sizes of 151 to 500 helmets, and a more complicated two-stage procedure for lot sizes of 91 to 150 helmets. The LAT procedures continue to fix the confidence levels at 90 percent. DOT&E’s LAT protocol, like its FAT protocol, assesses helmet BFD performance using statistical tolerance limits (discussed in ). In other words, the BFD LAT protocol, like the BFD FAT protocol, was based on binary outcomes-whether the BFD measurement exceeded the threshold or not. For example, the blue line corresponds to a penetration probability of 0.005 (current levels where manufacturers are operating), and the probabilities of acceptance for the three curves range from about 0.88 to about 0.99. In, the OC curves for the different lot sizes vary considerably and hence can have quite different manufacturer’s and government’s risks. The interpretation of an OC curve here is the same as that in: It is a plot of the probability of acceptance (passing LAT in this case) on the y axis versus the true penetration probability on the x axis. Shows the OC curves for the DOT&E LAT protocols for the three different lot sizes: 91 to 150 (black), 151 to 500 (red), and 501 to 3,200 (green). The goal of LAT is to assess whether the manufacturer’s helmets continue to conform, and thus the government is expected to assume greater risk at this stage. In comparing LAT and FAT, it is important to keep in mind that the manufacturer has already demonstrated the ability to meet specification requirements via FAT. Resistance to Penetration This section compares the OC curves of DOT&E’s LAT protocol with DOT&E’s FAT protocol and the Army’s original FAT protocol. Further, DOT&E’s FAT protocols are considerably less stringent (higher probabilities of acceptance for the OC curves) than their corresponding LAT protocols. This is primarily due to the different sample sizes (number of helmets and number of shots) as determined from ANSI standard. The OC curves for the LAT plans for the different lot sizes can vary a lot, indicating that the manufacturer’s and government’s risks can be quite different across lot sizes.

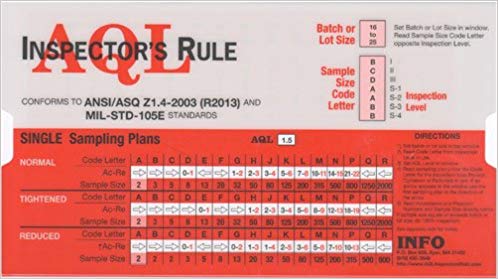

This chapter examines the operating characteristic (OC) curves for the Director, Operational Test and Evaluation’s (DOT&E’s) LAT plans and compares them with first article testing (FAT) protocols in the Army’s legacy plans and DOT&E’s plans. The number of helmets in the protocols is determined from an American National Standards Institute (ANSI) standard, and they vary by lot size. A random sample of helmets is selected from the production lot, and the helmet shells as well as hardware are tested according to the LAT protocol. Lot acceptance testing (LAT) is used to ensure that manufacturers continue to produce helmets that conform to contract specifications.

0 kommentar(er)

0 kommentar(er)